Chemours' Trusted Chemistry in Action: Driving Toward More Sustainable EV Batteries

Published 16 hours ago

Submitted by The Chemours Company

Electric vehicles (EVs) are an essential part of the clean energy transition. Through collaboration and advanced chemistry, we are helping accelerate the transition to EVs by contributing to more sustainable lithium-ion battery (LiB) manufacturing, longer driving ranges, and a reduced manufacturing footprint. LiBs have the potential to revolutionize the way we power EVs, but LiB manufacturers still have challenges to overcome existing manufacturing processes.1 These include:

- Decreasing LiB production cost to promote consumer adoption of EVs.

- Enhancing overall performance metrics to accelerate charging rates, extend driving range, and improve LiB power density.

- Manufacturing LiB components such as electrodes sustainably.

In 2024, we opened our Chemours Battery Innovation Center (CBIC), a state-of-the-art laboratory facility located at Chemours Discovery Hub in Newark, Delaware. The CBIC represents a multimillion-dollar investment to test and scale next generation battery technologies to enable more sustainable, cost-effective, energy-efficient, and high-performing batteries. The facility serves as a technical support lab for partners and customers to collaborate with Chemours’ engineers to iterate, pilot, and adopt novel approaches to fabricate cost-effective LiBs.

Advanced materials, such as our advanced fluoropolymer binders, are helping transform battery production by enabling dry, solvent-free battery electrode manufacturing that can contribute to more cost-effective and energy-efficient vehicles.

Today, most commercial lithium-ion battery electrodes are produced using a wet, slurry-based fabrication process that can involve the use of N-methyl-2-pyrrolidone (NMP), which is hazardous to human health and environment. Drying and solvent recovery systems also involve expensive and large machines, which consume a lot of energy during operation.

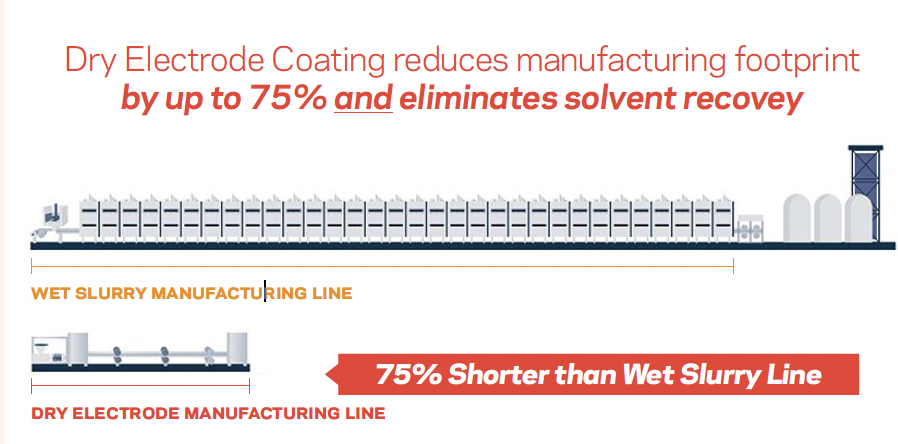

Moving to a dry electrode coating process using our advanced fluoropolymer binders eliminates the need for solvents and costly, energy-intensive drying and solvent recovery systems, making battery production more cost-effective and sustainable. Research2 has demonstrated:

- Energy consumption is reduced by approximately 47% and the LiB cell manufacturing cost is reduced by 20%.

- The manufacturing footprint is reduced by 75%.

- NMP emissions to the environment are avoided from solvent handling and evaporation steps.

In addition, dry coating technology also has the potential to enable higher energy density batteries, which could improve driving range.

Helping Scale Battery Innovations

Adopting dry electrode coating has clear benefits for the environment, manufacturing processes and cost efficiencies. Yet, the full benefits of this emerging technology are still being realized. For example, research into new battery technology such as energy-dense solid-state batteries (SSB) indicate dry electrode coating can be key to bringing SSB manufacturing to scale.3 As ongoing innovation in manufacturing and materials chemistry are inspiring battery innovations, Chemours advanced fluoropolymer binders are helping contribute to the adoption and scaling of more cost-effective, sustainable, high-performing solutions.

Learn more about how Chemours’ chemistry drives innovation in our latest sustainability report.

1 The Advantages of Dry Electrode Coating in Lithium Ion Battery Production: chemours-autoxev-drybinder-wp-final.pdf

2 11Liu, Y.; Zhang, R.; Wang, J.; Wang, Y. Current and Future Lithium-Ion Battery Manufacturing. iScience 2021, 24 (4), 102332. https://doi.org/10.1016/j.isci.2021.102332

3 Kong, L.; Wang, L.; Zhu, J.; Bian, J.; Xia, W.; Zhao, R.; Lin, H.; Zhao, Y. Configuring Solid State Batteries to Power Electric Vehicles: A Deliberation on Technology, Chemistry and Energy. Chemical Communications 2021, 57 (94), 12587–12594.

The Chemours Company

The Chemours Company

About The Chemours Company

The Chemours Company (NYSE: CC) is a global leader in providing industrial and specialty chemicals products for markets, including coatings, plastics, refrigeration and air conditioning, transportation, semiconductor and advanced electronics, general industrial, and oil and gas. Through our three businesses – Thermal & Specialized Solutions, Titanium Technologies, and Advanced Performance Materials – we deliver application expertise and chemistry-based innovations that solve customers’ biggest challenges. Our flagship products are sold under prominent brands such as Opteon™, Freon™, Ti-Pure™, Nafion™, Teflon™, Viton™, and Krytox™. Headquartered in Wilmington, Delaware and listed on the NYSE under the symbol CC, Chemours has approximately 6,000 employees and 28 manufacturing sites and serves approximately 2,500 customers in approximately 110 countries. For more information, visit chemours.com or follow us on LinkedIn.

More from The Chemours Company