Employees Team Up To Create New Safety Tool; Win Award

"As leaders, we want them to know that we’re looking out for their safety – they come first with us.”

Published 09-19-24

Submitted by Georgia-Pacific

AUGUSTA, Ga., September 19, 2024 /CSRwire/ - The team at Georgia-Pacific's Augusta Corrugated facility is raising the bar when it comes to safety.

They've been honored with the Fibre Box Association's 'Innovation in Safety' Achievement Award for a new tool they developed.

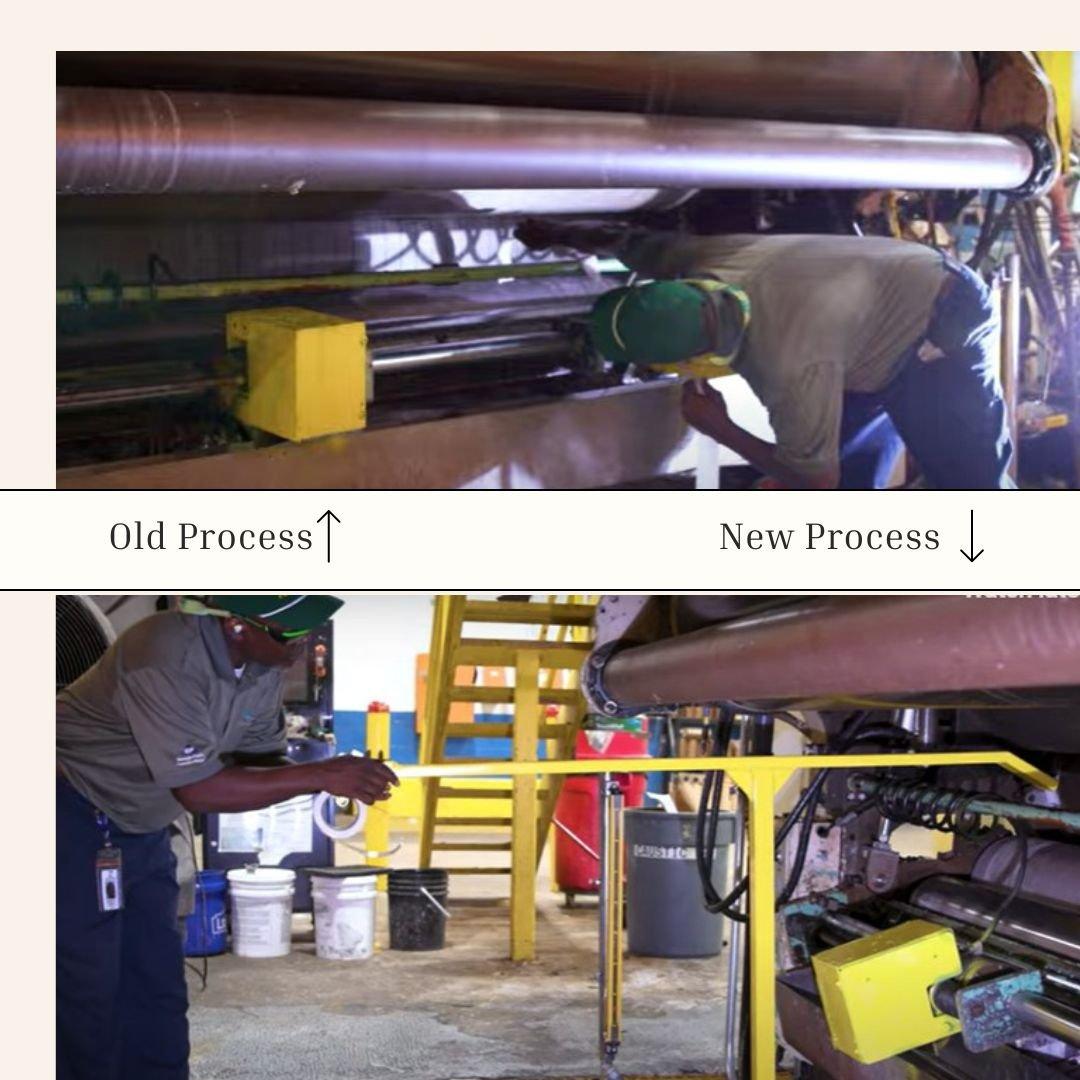

For years, employees faced significant risks when checking the gap between the glue roll and the corrugated roll on the single facer. The single facer is a large machine that uses heated corrugating rolls to form flutes that adhere to a liner paper, producing single face webbing for corrugated board.

Though it might sound like a small task, the risks involved were anything but minor.

Employees had to feed material just 4 thousandths of an inch thick into the running machine. To get an accurate read, they had to reach all the way to the nip point to push the material in while still holding on to it. This exposed them to extreme heat, pinch points, and possible crushing injuries.

Despite the dangers, the process had become routine.

“We were complacent. People were saying this is how we’ve been doing it for years. But that didn’t make it the right way,” said Daryl Harris, corrugator supervisor.

Recognizing the need for a quick and safe fix, the Augusta team got right to work. Leaders collaborated closely with the maintenance team and operators who use the equipment daily and are familiar with the risks. Together, they developed a solution in just two months!

It’s called a gap check stand, and it’s a game changer.

The new tool keeps employees completely away from the machine, eliminating risks like heat, pinch points, and crushing injuries. It’s also bolted to the floor to prevent it from being pulled into the single facer.

The impact has been huge.

Employees appreciate its simplicity and practicality. But the best part? It’s all about keeping them safe, and that’s what matters most.

“The way the Augusta team came together and quickly tackled the issue is truly remarkable,” said Paul Guy, operations manager. “When leadership engages with team members and provides a solution that is both safe and practical, it not only enhances safety but also empowers everyone to take ownership of their roles. This collaboration and commitment are what truly drives our success and is something I’m very proud of.”

Click here to read why the Martinsville Corrugated plant was also honored with the FBA Safety Award.

View original content here.

Georgia-Pacific

Georgia-Pacific

Based in Atlanta, Georgia-Pacific and its subsidiaries are among the world’s leading manufacturers and marketers of bath tissue, paper towels and napkins, tableware, paper-based packaging, cellulose, specialty fibers, nonwoven fabrics, building products and related chemicals. Our familiar consumer brands include Quilted Northern®, Angel Soft®, Brawny®, Dixie®, enMotion®, Sparkle® and Vanity Fair®. Georgia-Pacific has long been a leading supplier of building products to lumber and building materials dealers and large do-it-yourself warehouse retailers. Its Georgia-Pacific Recycling subsidiary is among the world’s largest traders of paper, metal and plastics. The company operates more than 150 facilities and employs more than 30,000 people directly and creates approximately 89,000 jobs indirectly. For more information, visit: gp.com/about-us . For news, visit: gp.com/news

More from Georgia-Pacific