Driving Sustainability Forward: Georgia-Pacific's Biomass Initiatives

Published 05-03-24

Submitted by Georgia-Pacific

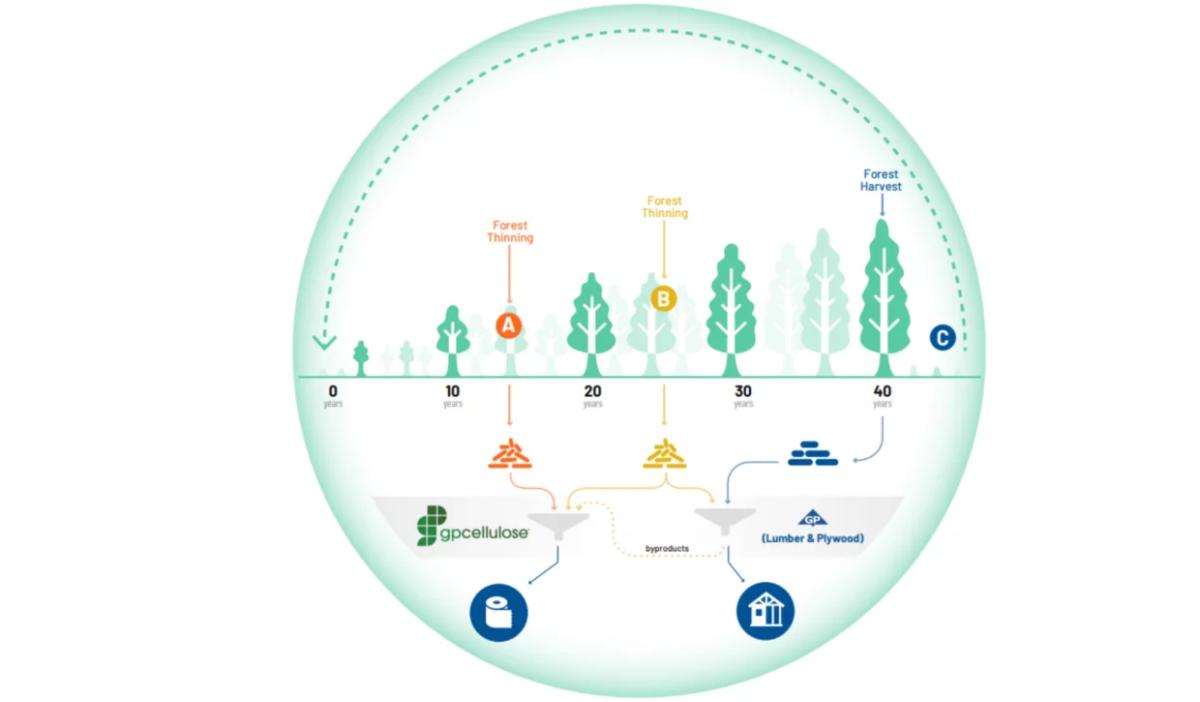

Georgia-Pacific's stewardship framework includes contributing to the success of communities where we operate, and ensuring we use natural resources thoughtfully. We responsibly source our timber and proactively monitor where our fiber comes from through our endangered forest mapping program. The company also supports wildlife conservation, uses renewable energy sources, and aims to reduce our waste responsibly.

At the same time, Georgia-Pacific continuously challenges and transforms how we practice responsible stewardship. We use biomass at our wood products facilities to generate thermal energy for production processes.

Biomass, considered carbon neutral by the U.S. Environmental Protection Agency (EPA), is a renewable organic material that comes from plants such as trees. It contains stored chemical energy from the sun produced by plants through photosynthesis, and can be used for heat, converted to liquid and fuels, and energy sources. Sources of energy include wood and wood processing waste, which is a primary raw material we use.

Using the entire tree – from bark to wood waste and other organic materials – biomass accounts for over 50% of our energy needs. For example, twenty-one of Georgia-Pacific's Building Products facilities use biomass to make steam or heat to produce various products, such as plywood. Overall, GP has decreased our reliance on solid fossil fuels by 72% since 2013 and replaced this energy demand with either natural gas or biomass. Shifting energy choices to biomass and natural gas has resulted in a decrease in our greenhouse emissions.

In 2019, Georgia-Pacific’s Naheola mill in Pennington, Alabama, completed a coal boiler upgrade to biomass. This facility, which produces consumer products such as bath tissue and paper towels, replaced the legacy boilers as part of a strategy to produce energy more efficiently. The initiative, which also reduced water consumption, emissions, and particulate matter, reduces greenhouse gas emissions and the need for landfill disposals, was chosen by the ENERGY STAR® Industrial Partners as a Top Project.

Georgia-Pacific depends on healthy working forests for its products. As a manufacturer that practices responsible sourcing, biomass is one of the technologies we use to consume fewer resources and lessen emissions, while creating more value for our partners, consumers, and communities.

Learn more about Georgia-Pacific’s approach to environmental stewardship by viewing the 2023 Stewardship Report.

View original content here.

Georgia-Pacific

Georgia-Pacific

Based in Atlanta, Georgia-Pacific and its subsidiaries are among the world’s leading manufacturers and marketers of bath tissue, paper towels and napkins, tableware, paper-based packaging, cellulose, specialty fibers, nonwoven fabrics, building products and related chemicals. Our familiar consumer brands include Quilted Northern®, Angel Soft®, Brawny®, Dixie®, enMotion®, Sparkle® and Vanity Fair®. Georgia-Pacific has long been a leading supplier of building products to lumber and building materials dealers and large do-it-yourself warehouse retailers. Its Georgia-Pacific Recycling subsidiary is among the world’s largest traders of paper, metal and plastics. The company operates more than 150 facilities and employs more than 30,000 people directly and creates approximately 89,000 jobs indirectly. For more information, visit: gp.com/about-us . For news, visit: gp.com/news

More from Georgia-Pacific