Now Reading

Henkel Highlights Solutions for Next-Generation Design and Manufacturing of Battery Components During Battery Show North America

Latest material solutions enable simplified design, process efficiency, sustainability and increased performance of battery components for Battery Electric Vehicles

Henkel Highlights Solutions for Next-Generation Design and Manufacturing of Battery Components During Battery Show North America

Latest material solutions enable simplified design, process efficiency, sustainability and increased performance of battery components for Battery Electric Vehicles

Published 09-14-23

Submitted by Henkel

MADISON HEIGHTS, Mich., September 14, 2023 /CSRwire/ - As global sales of electric vehicles are set to achieve another record year in 2023 (source: IEA), manufacturers are continuing to innovate in the areas of design and production to further improve performance, range, process efficiency and sustainability. Material solutions, including bonding, thermal management, sealing and functional coatings play a pivotal role in enabling these goals. Henkel will showcase technologies & products advancing battery components at Booth #1001 during this year’s Battery Show North America, taking place September 12-14 in Novi, Michigan.

Enabling Simplified Battery Designs

Simplifying battery designs with new approaches like Cell-to-Pack and Cell-to-Vehicle architectures enable BEV manufacturers to reduce weight, cost and improve energy density. However, eliminating battery module housings require increased mechanical performance requirements. Thermally Conductive Adhesives tolerate high mechanical and thermal impact, while continuing to deliver necessary heat dissipation requirements.

Increasing Process Efficiency

Meeting high-volume production demand for battery components requires highly efficient application processes. Through our robust network of dispense partners, Henkel offers automated, fast application processes, while reducing manufacturing steps. Henkel’s Loctite EA 9400 battery safety coating, for example, is applied through precise flat streaming, eliminating the need for time-consuming masking.

Increasing Sustainability

Conductive Electrode Coatings enable higher energy density due to improved conductivity on the battery cell level – helping to increase range without increasing the size of the battery pack. While traditional process steps include wet mixing of the material, Henkel’s process involves dry mixing, reducing energy demand by greater than 30 percent, reducing equipment footprint by 70 percent and providing cost savings potential in cell production of greater than 10 percent.

In addition to seeing the technology at Booth #1001, conference attendees can learn more during a technical presentation on September 13, from 2:30 – 3 p.m. during the Battery in Use track.

Increasing Performance

High-voltage battery components, such as on-board chargers, inverters, converters, e-motors and more, require protection and heat management simultaneously. Thermal potting compounds transfer heat away from embedded electronic components, while offering protective benefits of traditional potting, such as vibration/shock resistance, service life resilience, corrosion protection and chemical protection. Live application demonstrations of the technology will be offered at Booth #1001 in partnership with Henkel equipment provider, bdtronic, every hour on the hour during the show.

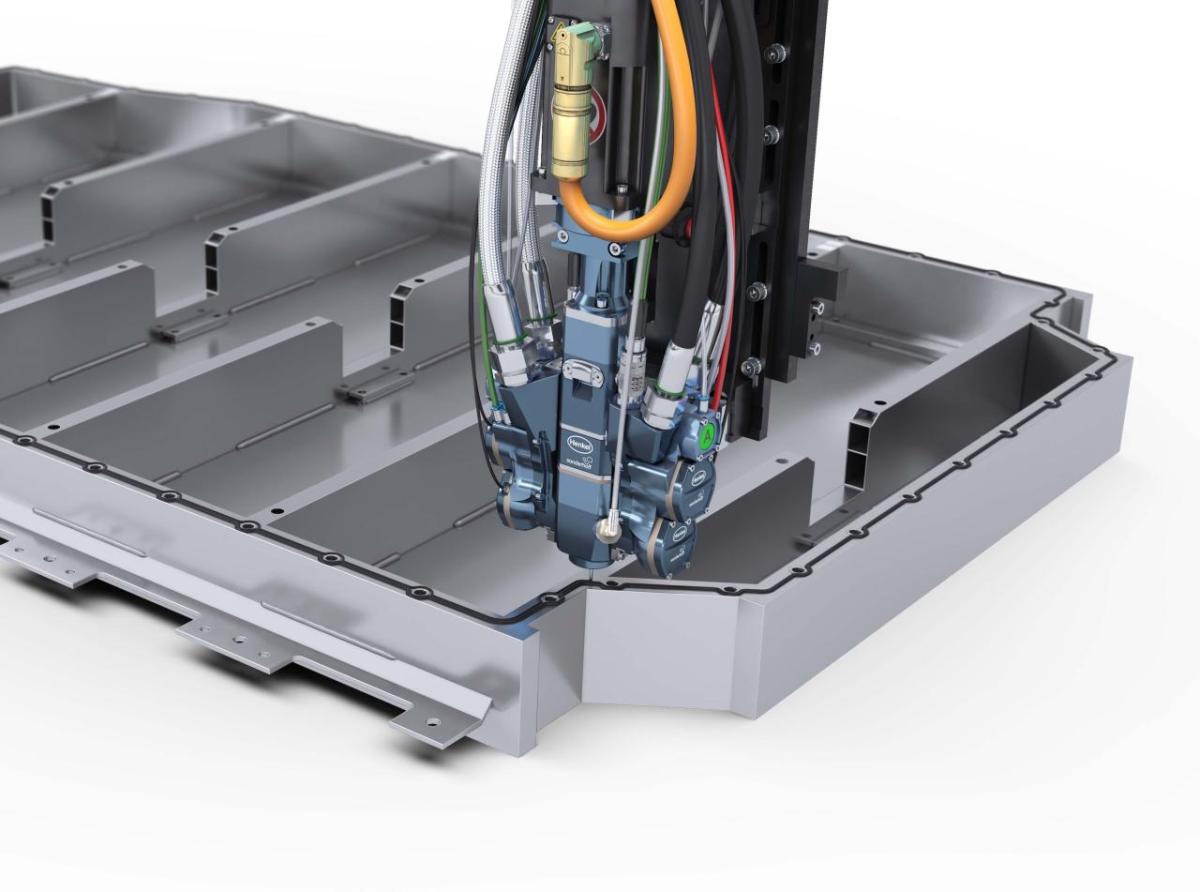

Environmental influences such as moisture, corrosion and dust can negatively impact the life of battery systems. Henkel’s Sonderhoff Formed-in-Place-Foam-Gasket technology seals battery housings, protecting them against splash water and weather influences.

Henkel

Henkel

About Henkel in North America

Henkel’s portfolio of well-known brands in North America includes Dial® soaps, Persil® and all® laundry detergents, Snuggle® fabric softeners, Schwarzkopf® hair care, as well as Loctite®, OSI®, Technomelt® and Bonderite® adhesives. With sales close to 6.6 billion US dollars (6 billion euros) in 2023, North America accounts for 28 percent of the company’s global sales. Henkel employs around 8,000 people across the U.S., Canada and Puerto Rico. For more information, please visit http://www.henkel-northamerica.com and on X (Twitter) @Henkel_NA.

About Henkel

With its brands, innovations and technologies, Henkel holds leading market positions worldwide in the industrial and consumer businesses. The business unit Adhesive Technologies is the global leader in the market for adhesives, sealants and functional coatings. With Consumer Brands, the company holds leading positions especially in laundry & home care and hair in many markets and categories around the world. The company's three strongest brands are Loctite, Persil and Schwarzkopf. In fiscal 2023, Henkel reported sales of more than 21.5 billion euros and adjusted operating profit of around 2.6 billion euros. Henkel’s preferred shares are listed in the German stock index DAX. Sustainability has a long tradition at Henkel, and the company has a clear sustainability strategy with specific targets. Henkel was founded in 1876 and today employs a diverse team of about 48,000 people worldwide – united by a strong corporate culture, shared values and a common purpose: "Pioneers at heart for the good of generations.” More information at www.henkel.com.

More from Henkel