How Energy Modeling Can Save Your Project Millions

Take advantage of energy modeling during the design phase of a manufacturing facility to accelerate schedules and reap significant savings in both capital and operating expenses.

Published 08-30-23

Submitted by CRB

By Jeff Wegner, PE, CEM, LEED AP Fellow - Energy + Sustainability and Nick Dove, PE, LEED GA Mechanical Engineer

Buying a house is often the most expensive purchase of our lives. A home inspection can help prospective homebuyers make a more informed decision and potentially save thousands of dollars in maintenance, repairs, and other unwanted costs. Despite these benefits, some choose to forgo this valuable process to save a small expense.

Not having a building energy model for the design of a manufacturing facility is like this. In our experience, only a small fraction of project owners (10–20%) take advantage of energy modeling when designing a new building or assessing an existing building due to the added upfront cost. Thus, most are missing the opportunity to model for energy efficiency as a way to reduce energy consumption and, thus, operating expenses.

In fact, the most attractive reason to create a building energy model during the design phase is to lower both capital costs and operating expenses.

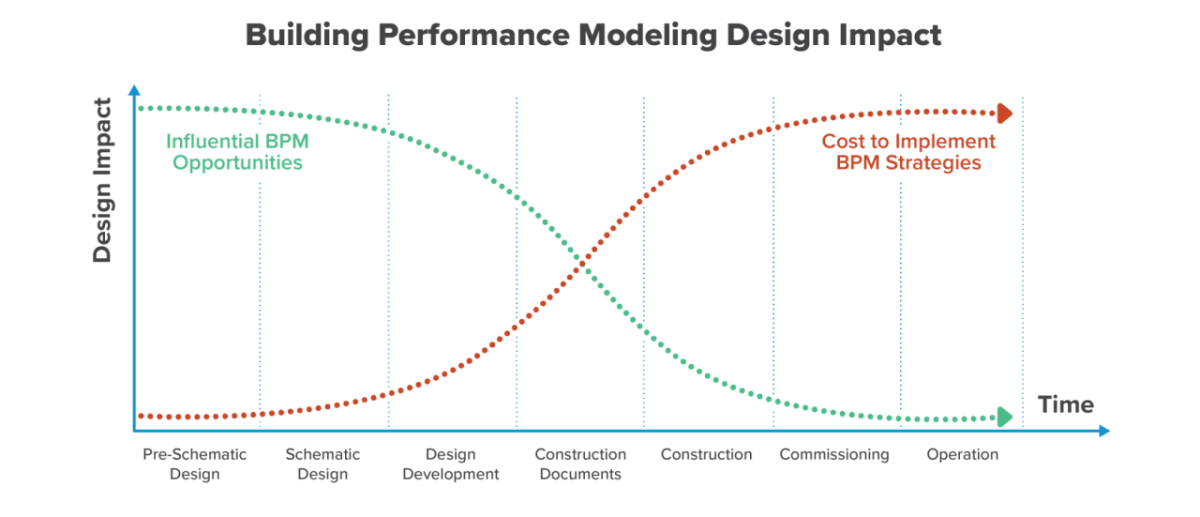

Making decisions at the outset of your projects about energy use—without the information that energy modeling can provide—will have lasting repercussions, at times amounting to millions of dollars in unnecessary utility costs. Given that energy modeling is inexpensive and ensures you make the wisest long-term decisions, we recommend performing energy modeling as early in the design phase as possible.

What is building energy modeling?

Energy modeling is used during the design of a manufacturing facility to quantify and optimize energy use of the building, process equipment, and supporting mechanical systems. In addition to energy consumption, these models include estimates of peak fuel demands, carbon emissions, water use, and renewable energy. Building energy modeling can identify the most efficient path, significantly reduce both capital and operating costs, and address the sustainability challenges that highly-regulated manufacturing facilities face.

How is building energy modeling applied?

The type of building dictates how energy modeling is applied. For a commercial building, such as a corporate headquarters, the building envelope heavily impacts energy expenditures, and internal heat gains are low. For these reasons, energy modeling in the commercial sector tends to focus on architecture. Glazing and the use of renewables are important, and commercial projects are more likely to aim for LEED certification, which often triggers the need for a building energy model.

Building energy modeling for pharma manufacturing facilities and their inherent processes is different. The building envelope—often a box with limited windows (e.g., a cleanroom)—is less important in terms of energy use intensity (EUI). Instead, mechanical systems needed for process technology take on far greater importance. This is why we tend to focus on mechanical energy modeling because there is significantly more CapEx and OpEx involved. In addition to space heating and air change rates, there is also steam used for sterilization and to distill water for injection (WFI), both reliant on mechanical boilers and using considerable energy. These processes also generate heat and humidity, both of which must be removed from the building.

How can energy modeling reduce costs?

Energy models for a design can help you weigh the various upfront and long-term costs associated with your project to save money, like the example given in our case study demonstrating how site selection impacted one project’s utility costs by $80 million. We examine the energy implications for each of the following situations, contextualizing utility costs over time with the initial price tag, and allowing you to determine areas where you can save.

Compare types of equipment

Choosing between different types of systems (e.g., a heat pump versus an electric boiler) involves an internal discussion between the energy modeler and the mechanical engineer. Together, they weigh various options to make the best decision.

Compare equipment from different manufacturers

Consider a chiller with better peak load performance versus one that runs more efficiently under part load conditions. In this case, if there is a difference in equipment cost, the payoff of energy gains over time must be calculated to make the best decision.

Total cost of ownership (TCO)

In this case, when the client wants to know the solution with the greatest value or lowest life cycle cost, we weigh the capital cost versus the energy cost.

Optimize controls

Often an energy modeler can discover new ways to reduce energy consumption through various control strategies.

Estimating cost savings and payback time of an energy model

For energy modeling to be attractive, the costs of commissioning an energy model should be recovered within three years through reduced capital expenditures or energy savings. In fact, by comparing the costs of energy modeling with predicted energy savings, the typical payback takes less than two months for commercial buildings. Of course, every project is unique and these numbers won’t necessarily apply to a pharmaceutical manufacturing plant.

How building energy modeling supports sustainability goals

Another reason to include an energy model is to achieve corporate sustainability goals. Sustainable energy solutions continue to gain popularity and most companies have decarbonization design standards that require alternatives to natural gas boilers and reduce unnecessary steam heat. We are often challenged to provide the lowest-cost option that meets user requirements or corporate sustainability goals. This creates a conflict between the total cost of ownership and the lifecycle cost, which is both CapEx and OpEx over the long term.

One of the challenges with decarbonization alternatives is that they can cost more. But when we use an energy model, and right-size the systems, we find that even 10% energy savings can translate to significant cost savings for a large manufacturing facility.

Corporate sustainability commitments could also include net zero carbon, meeting an EUI target based on a code mandate or standard. Energy models predict carbon consumption and provide the data needed to make decisions about, for example, the number of PV panels needed to offset carbon use.

Many companies are also committing to reducing water use. Water is an increasingly valuable commodity, one for which the tradeoff of consuming more energy to save water may be worthwhile, especially when clean energy alternatives are readily available.

Building energy modeling for LEED-certified projects

Although LEED certification weighs heavily on energy consumption—and whether green energy is being sourced—it also takes into account many other aspects, such as location, water, and the wellness of building occupants. By focusing, for example, on glazing, views to the outside, and indoor air quality, energy use might actually increase. Running energy models alongside your LEED scoring pursuits allows you to identify these inconsistencies in goals early on.

How does energy modeling work? And how are potential energy cost savings calculated?

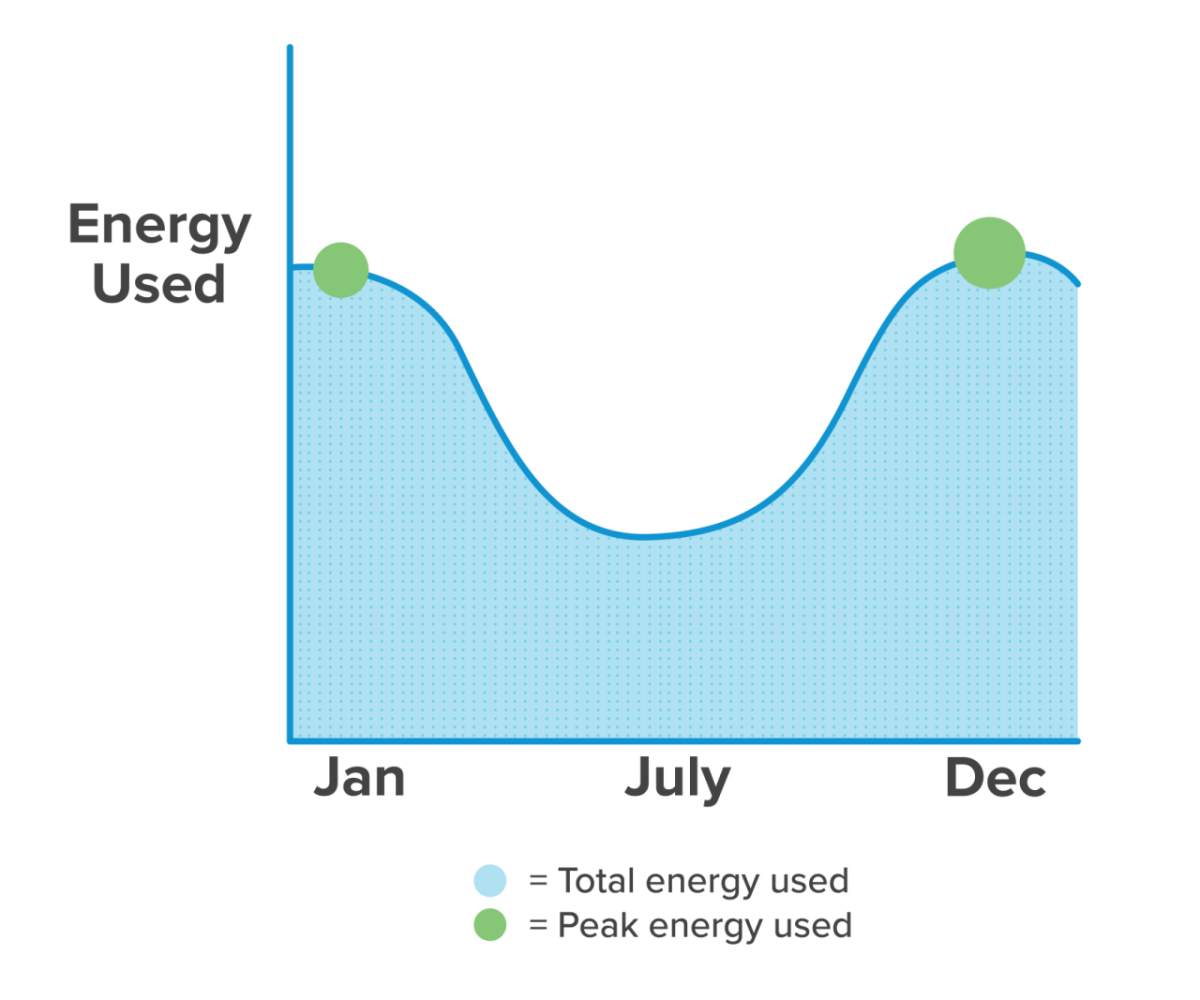

Mechanical engineers calculate equipment energy loads to size equipment for the upper end, or peak, of energy use of a process. Given this load, a mechanical engineer estimates the appropriate size of a chiller or a boiler. Using software and HVAC load calculations, they will typically oversize equipment to ensure the maximum load on the plant never exceeds the available capacity. This takes into account the need to function at peak loads that, for heating and cooling, normally occur in summer and winter months, as well as meet unknowns like a potential expansion.

Energy modelers apply different thinking and methodology to calculate energy use than mechanical engineers. Using an 8760 energy model, an energy modeler strives to find the equipment sweet spot. An 8760 model refers to the number of hours in one year, and it simulates energy use for each hour throughout the year—sometimes as often as every five minutes—to prove a more accurate assessment of what is needed most of the time.

Using this detailed data, the energy modeler right-sizes the equipment to meet code energy use specifications or LEED requirements. Usually, this results in downsizing the mechanical engineer’s recommended equipment, while ensuring the equipment works within the necessary range of energy loads. Additionally, a mechanical engineer assumes there are no internal heat gains in winter loads, such as employees, lights, and computers. An energy modeler takes into account more realistic schedules of operation.

Combining the expertise of mechanical engineers with that of energy modelers can immediately reduce capital costs prior to construction by right-sizing expensive equipment, such as boilers, chillers, and HVAC systems. And, for equipment like heat recovery chillers (HRCs), downsizing actually allows them to operate more efficiently. In some cases, these cost savings may not be obvious to a client, as it’s part of our internal process of optimizing energy use.

Iterative and collaborative energy modeling

Depending on the scope of desired energy modeling, our process can extend through three steps of design and contain different degrees of detail. These types of building energy modeling include:

Schematic design

This first step is a quick way to represent the space. These are simple energy models—approximations used to make quick decisions—and include a list of proposed equipment. A schematic design doesn’t include all the rooms within each space as these may change over time.

It’s easiest to make changes at this stage before equipment has been purchased. We can anticipate expected LEED points and identify challenges.

Detailed design

Typically, the building’s site orientation is set by this phase while we make a more accurate and detailed model. We may continue to run studies to assess minor equipment choices and iterate to consider options. For example, we might be assessing two different chiller manufacturers based on the efficiency of their equipment.

Code compliance or LEED submission design

This is a fully detailed energy model, with everything documented and consistent with the design drawings. Energy models are necessary to meet the city code requirements on a performance path (e.g., IECC), though they are not needed for a prescriptive path. Other models are submitted to USGBC to determine LEED certification. Some models are used for both.

How to get the most out of your energy model

1. Start early in the design

Project schedules tend to be tight. Once construction begins, there may not be leeway to compare various heating, cooling, or energy recovery options, especially since this can change schedule and adversely affect costs. This is why it’s important to begin energy modeling during the schematic design phase—or even as early as strategic facility planning—to have the greatest influence on the project direction. Many projects that forego early energy modeling end up spending more to implement the same strategies later.

2. Gather inputs from all disciplines

Using a floor plan and building information modeling (BIM) software (e.g., a Revit 3D digital model), we create a unified energy model. This includes inputs from all project disciplines, including architects (e.g., type of glazing, intended use of each space), mechanical and electrical engineers (e.g., internal heat gains, HVAC system), process engineers, and the team responsible for the building schedule.

We also gather information from our clients, who share target costs, EUI, and sustainability goals.

3. Perform building energy simulations

We primarily use IESVE for building the analytical energy model and running energy simulations. This involves many steps, such as modeling the 3D geometry, replicating the construction assemblies, building the load profiles for each space, setting up the various systems, tuning the controls, and assessing the reasonableness of the outputs.

4. Decide how to apply outputs

Based on discussion with architects, mechanical engineers, and the client, we determine how to leverage the model outputs for best results. This iterative process, comparing various options, is based on our extensive project modeling, design, and execution experience.

Energy modeling gives you confidence in your building’s design and your capital investment

While it’s true you may not need a building energy model to design and build your facility, it’s also true that this exercise often pays for itself—and quickly. But designing an energy-efficient facility, one with right-sized and optimized mechanical systems, requires experienced energy modelers.

Our building energy models have helped our clients to save millions of dollars in their facilities; for detailed examples of how we’ve significantly reduced costs with energy modeling, download our case studies here.

- Case study 1: Local utility rates affect site selection by $80 million

- Case study 2: Reducing air change rates from 40 ACH to 12 ACH

- Case study 3: Heat recovery chillers are almost always a good choice

Want to learn how energy modeling can reduce the capital and energy costs on your next building project? Contact our team.

CRB

CRB

CRB is a leading global provider of sustainable engineering, architecture, construction, and consulting solutions to the life sciences and food and beverage industries. Our innovative ONEsolution™ service provides successful integrated project delivery for clients demanding high-quality solutions -- on time and on budget. Across 21 offices in North America and Europe, the company's nearly 1,800 employees provide world-class, technically preeminent solutions that drive success and positive change for clients and communities. See our work at crbgroup.com, and connect with us on social media here.

More from CRB