Essity 2022 Annual and Sustainability Report: Plastic and Packaging

For the well-being of people and planet

Published 06-01-23

Submitted by Essity

Originally published on Essity.com

Plastic

The production of fossil plastic has a negative impact on our planet as it releases carbon emissions into the atmosphere and thereby accelerates the existing climate crisis. Plastic waste and pollutants threaten human welfare as well as wildlife and biodiversity. Nations worldwide, with the European Union (EU) at the frontline, are placing bans on single-use plastics and transitioning toward a more circular economy that considers every stage of a product’s journey – before and after it reaches the customers and consumers. In parallel, plastic is required to ensure necessary levels of sanitation, safety and functionality for hygiene and health products. Our industry must change how we design, use, and reuse plastic by shifting from linear to circular business models. This calls for creative thinking, new business models and partnerships where we develop new solutions that lead to less waste.

Packaging

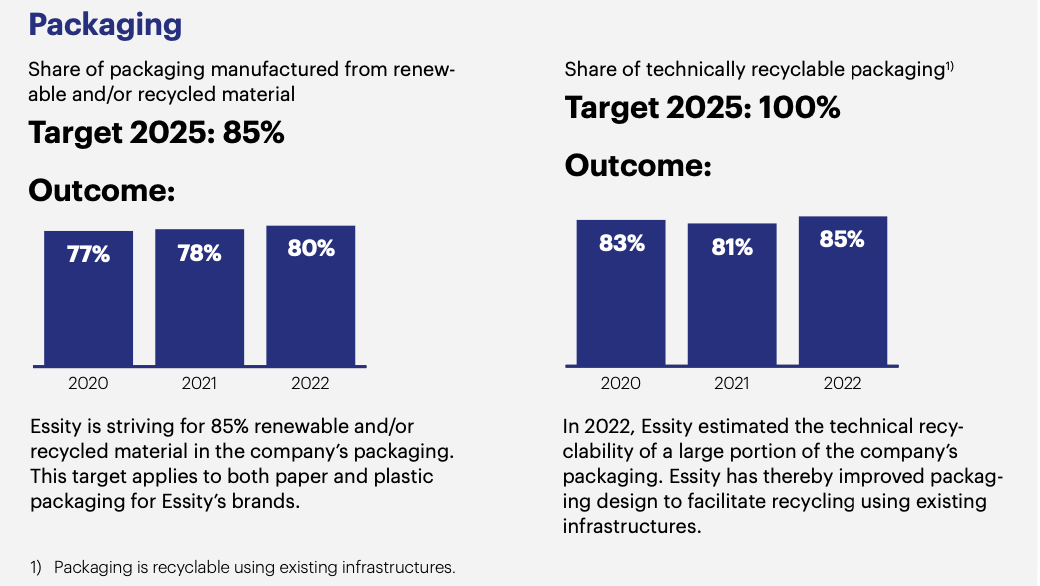

Essity has ambitious targets to reduce the total amount of primary plastic in the company’s packaging, to increase the use of renewable or recycled plastic and to make all plastic packaging recyclable. Our packaging strategy includes innovating for increased circularity while simultaneously reducing existing greenhouse gas emissions.

- In 2022, Essity’s packaging for hygiene and health products contained on average 80% renewable or recycled material. By 2025, we aim to achieve 100% recyclability, 85% renewable or recycled materials in our packaging, of which 25% recycled content in plastic packaging.

- We reduce our carbon footprint primarily by using recycled plastic packaging materials. To achieve more rapid results in the development of better packaging material, Essity is part of the Ellen MacArthur Foundation and Circular Plastic Alliance, among other organizations.

The UN began negotiations for an International legally binding instrument to end plastic pollution in November 2022. This global treaty will focus on all plastic products, including packaging. The multilateral negotiations on the treaty are expected to conclude in mid-2025. Essity joined the Business Coalition for a Global Plastics Treaty. This new Coalition led by the Ellen MacArthur Foundation and WWF endorses a common vision, by providing a clear voice in the treaty negotiations to amplify the call for an ambitious and effective global treaty.

Plastic in our products

Essity aims to reduce and replace primary fossil-based plastics in our products and minimize the waste in our production and after use. By developing smarter designs, new services, and innovating to find alternative materials, we ensure less use of primary fossil plastic in general, less single-use plastic in particular, while also reducing the environmental impact through the product life cycle.

Essity constantly reviews product design to enable more sustainable consumption. One example is how we dispense our Tork tissue, which can reduce tissue consumption by more than 25%. In 2022, TENA Lights Sensitive were also launched, where the pads come in a renewable paper packaging contributing to less plastic waste and reducing the carbon footprint by using at least 50% plant-based materials in products and packaging.

We are broadening our collaboration with customers and consumers to better understand how we can support their sustainability strategies and targets, while helping them make more sustainable choices. Essity aims to create more value using less resources and innovate and design products that fit into a circular society. We strive to replace primary fossil-based plastics with renewable materials derived from plants such as corn or sugar cane.

Waste

To reduce waste arising from Essity’s production and waste after use, we are developing products and packaging containing less primary fossil-based plastic and more circular solutions.

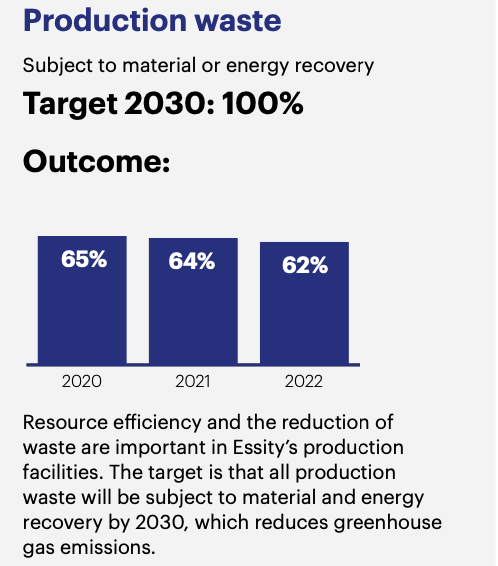

Production waste

The target is that all production waste will be subject to material and energy recovery by 2030. Recycling or extracting energy from the waste instead of sending waste to landfill reduces greenhouse gas emissions. For example, recovered material from tissue manufacturing can be used as raw material for other industries, such as in the construction industry.

Waste after use

We can create less waste after use through the principles Reduce, Reuse and Recycle. Essity strives to be more resource efficient, develop smarter designs and reduce materials in our products and packaging. Our services are constantly improving, and new designs are utilized to reduce waste, and thereby cut greenhouse gas emissions.

Most of our packaging is recyclable and we are working to optimize other packaging. We are reducing and replacing primary fossil-based plastic in our packaging and products with renewable or recycled materials. Essity is also working to develop smarter designs and innovative plastic materials to reduce environmental impact. We are cooperating with customers, consumers, suppliers, and other partners to identify more sustainable and circular solutions. A challenge in many markets is the lack of infrastructure for collecting used packaging or products. Essity therefore supports national initiatives for large-scale recycling of packaging.

Circularity

Essity has integrated circularity in the company’s business model, from responsible raw material procurement, more resource-efficient production with a smaller climate footprint, to circular solutions that enable customers and consumers to minimize waste.

We carry out circularity assessments as part of the innovation process to obtain a better understanding of how waste can be avoided during and after use. One example is TENA SmartCare, where product use is optimized and waste reduced through digital monitoring so the product is replaced at the right time and fewer and thinner products are used.

Water consumption

Water shortages and contaminated water have a negative impact on people, societies and the environment, and unsustainable water use could lead to the loss of biodiversity. This also affects Essity’s operations. Water risks differ around the world, and we assess risks and impacts individually for our tissue production facilities, both from a geographic and an operating perspective. Water is mainly needed for transporting fiber during the production process. We circulate water several times in production to help reduce energy use for heating and treatment of water. Most of the water is treated after use and is discharged.

Environmental permits for tissue plants also include limits for typical pollutants, such as chemical oxygen demand, phosphorus and nitrogen. Essity is investing in new wastewater treatment technology to meet the higher requirements on quality of discharged water. This is particularly important in locations where water is a resource shared with many different users, such as along major rivers, where the temperature of the water released must also be carefully monitored. For a number of years, we have actively worked to reduce the amount of water used and the levels of suspended solids and organic content (BOD), with a main focus on improving our water management.

Partnership to reduce environmental impact

Essity works together with various players such as non-governmental organizations (NGOs) on both environmental and social issues, inter-governmental organizations (IGOs) such as the World Health Organization, European Union, and the OECD, as well as with trade and industry associations.

Essity has been a member of the UN Global Compact Action Platform on Climate Ambition since 2017. The platform provides an opportunity for collaboration between companies and important stakeholders to address the issues of limiting and adapting to climate change.

We take part in discussions throughout the value chain to promote the implementation of circular economy solutions designed to tackle waste, including the CGF, Edana, Ellen MacArthur Foundation and RecyClass. Through CGF’s Coalition of Action on Plastic Waste, Essity works together with customers, other companies, and organizations to jointly reduce plastic waste and strive to improve social systems, so that no plastic waste is disposed in nature.

Essity is a partner in the Ellen MacArthur Foundation’s Network, which provides a forum to share, learn and implement ideas to implement and scale circular economy solutions for products, packaging, and services, and to jointly promote societal change. We are part of the New Plastic Economy initiative, which is aligned with and impacts external prerequisites for Essity’s target to ensure that all packaging is 100% recyclable and to increase the use of recycled plastic by 2025.

Read more about Essity’s strategic priorities, earnings and leading sustainability work in the Annual and Sustainability Report 2022, which can be downloaded at www.essity.com.

To access the digital short version, please click here.

Essity

Essity

Essity is a leading global hygiene and health company that develops, produces and sells Personal Care (Baby Care, Feminine Care, Incontinence Products and Medical Solutions), Consumer Tissue and Professional Hygiene products and solutions.

Our vision is; Dedicated to improving well-being through leading hygiene and health solutions. The name Essity stems from the words essentials and necessities. Sales are conducted in approximately 150 countries under many strong brands, including the leading global brands TENA and Tork, and other brands, such as Leukoplast, Libero, Libresse, Lotus, Nosotras, Saba, Tempo, Vinda and Zewa. Essity has about 48,000 employees and net sales in 2017 amounted to approximately 12.8 bn USD (SEK 109bn, EUR 11.3bn). The business operations are based on a sustainable business model with focus on value creation for people and nature.

The company has its headquarters in Stockholm, Sweden, and is listed on Nasdaq Stockholm. Essity used to be part of the SCA Group.

About Tork

Tork is a brand of Essity. Essity is a leading global hygiene and health company that develops personal care, professional hygiene and consumer tissue products and solutions. Essity offers Tork paper towels, toilet paper, skin care products, facial tissue, wipers, wet wipes, napkins and other hygiene products for washrooms, wash stations, healthcare areas, food and beverage handling, food preparation, manufacturing and maintenance. For more information, visit http://www.torkusa.com/

More from Essity