Add to Subtract: How Kimberly-Clark Is Boosting Sustainability With a Simple Addition to Product Packaging

Published 04-23-20

Submitted by Kimberly-Clark Corporation

The sustainability teams at Kimberly-Clark know that small innovations to reduce waste can add up when it comes to protecting the environment.

Kimberly-Clark’s Tuas manufacturing plant in Singapore is reducing packaging waste through their Edge Board Projector project, which improves packaging strength by adding a small cardboard edge to boxes. Prior to this initiative, Kimberly-Clark’s packaging material had to be thick to withstand the stacking, distribution and delivery of the company’s products. With the addition of the well-designed add-on, the team is now able to use thinner cardboard packaging material.

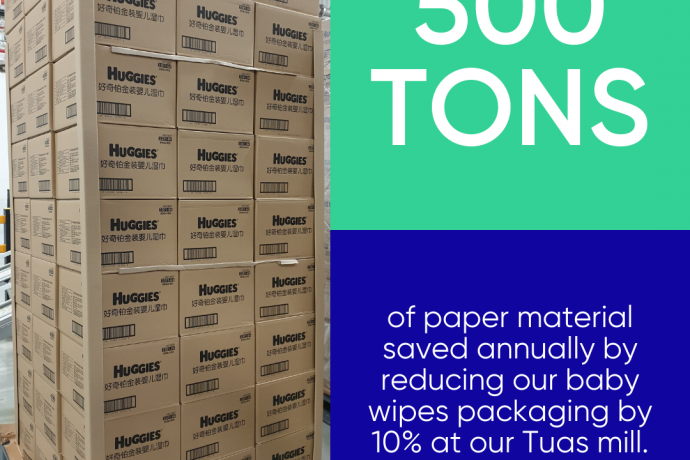

This simple change has reduced the thickness of the packaging material for Kimberly-Clark’s baby wipes by nearly 10%. This reduction helps the mill save approximately 500 tonnes of paper material per year. In addition, this effort has increased container loading capacity by 30% and will help lower the mill’s carbon footprint by 9,000 metric tonnes per year.

The improvements to the packaging efficiency and its redesign were done to help contribute to Kimberly-Clark’s sustainability goals, including a 40% reduction of greenhouse gases by 2022.

Kimberly-Clark Corporation

Kimberly-Clark Corporation

Kimberly-Clark and its trusted brands are an indispensable part of life for people in more than 175 countries. Fueled by ingenuity, creativity, and an understanding of people's most essential needs, we create products that help individuals experience more of what's important to them. Our portfolio of brands, including Huggies, Kleenex, Scott, Kotex, Cottonelle, Poise, Depend, Andrex, Pull-Ups, GoodNites, Intimus, Plenitud, Sweety, Softex, Viva and WypAll, hold No. 1 or No. 2 share positions in approximately 70 countries. We use sustainable practices that support a healthy planet, build strong communities, and ensure our business thrives for decades to come. We are proud to be recognized as one of the World's Most Ethical Companies® by Ethisphere for the sixth year in a row. To keep up with the latest news and to learn more about the company's 150-year history of innovation, visit kimberly-clark.com or follow Kimberly-Clark on Facebook, Instagram or LinkedIn.

More from Kimberly-Clark Corporation